Craft: Folger + Burt Architectural Hardware

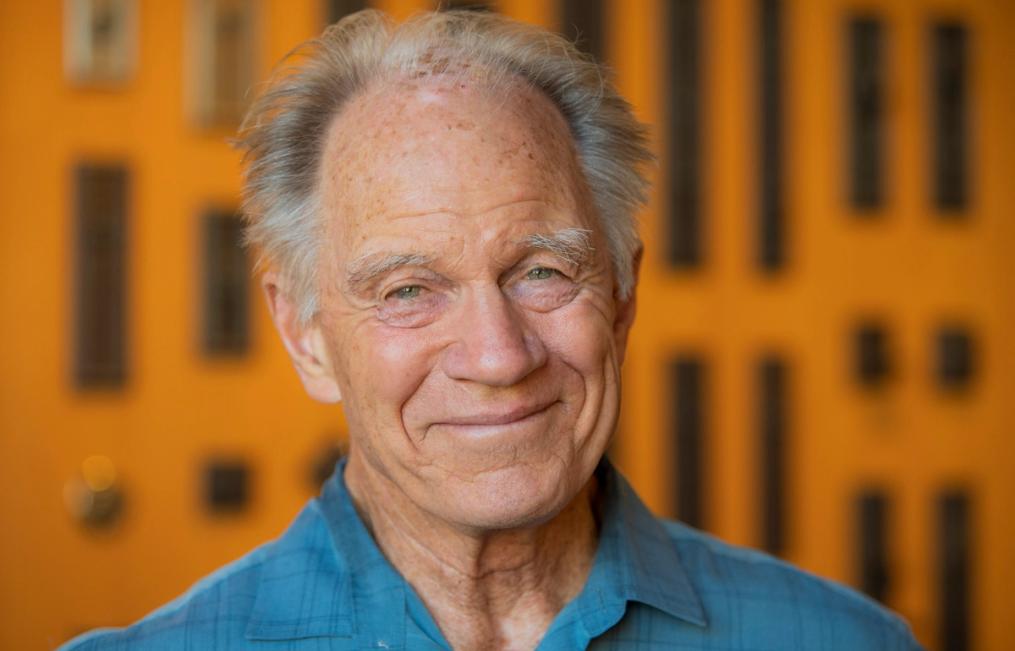

For this installment of our CRAFT series, we spoke with Tim Folger, founder of Folger + Burt Architectural Hardware. Their SF showroom is home to an impressive collection of intricate, detailed decorative hardware, and their team has expertly crafted custom pieces for a number of our projects.

How did you become interested in architectural hardware? Tell me about your background.

A native Northern Californian, I loved exploring the early buildings of Old Monterey, the adobe missions, and old barns along the coast. I saw simple hand wrought ironwork on whitewashed doors and in the mission livery stable that bore the hand of the maker. Blacksmiths had turned out humble fittings with a refined grace that seemed perfectly suited to the 150-year-old buildings. The timeless beauty of that hardware always stuck with me.

I was also lucky to grow up in an Eichler home on the peninsula, an all redwood and glass pavilion surrounded by a million green leaves. I sat there one day with a book on Italian art as my mother explained how fresco painters had to plan strategically so that they could accomplish their work before the plaster dried. A couple of lessons started to take shape. First, that the beauty of our house had much to do with the redwood grain all around me; it was art embedded in the structure itself. Second, if you are not Mother Nature, you need to deliberately design and execute to create beauty. See it, plan it, and get it done before the plaster dries. Those lessons pushed me into a career as a homebuilder and eventually back to my love of that old ironwork. Done well, it could be as integral to architecture as the redwood grain.

How did your early career and previous experience in the industry influence what you aimed to create with Folger + Burt?

While studying world literature at UC Berkeley, I discovered traditional Japanese woodworking hand tools - affordable yet very high quality. The Eichler had primed me to appreciate the nature of traditional Japanese architecture and the commitment required to create those structures while starting to make a living as a carpenter. I taught myself to build houses, doors, windows, cabinets, light fixtures, furniture, even an occasional canoe paddle. Both inventing and reinventing was rewarding for both me and for my clients during my twenty years as a general contractor.

The same passion for working with wood was reignited in metal by a surprise meeting in the mid-90’s with a kindred soul, another builder who had devoted himself to the world of patternmaking, the foundry, and the machine shop to make original hardware in bronze. His company, Sun Valley Bronze, rose steadily into a pre-eminent position while spurring a renaissance in the industry and a renewed interest in extraordinary hardware.

I spent a week at the foundry helping to make the hardware for a current job, an old style “carriage house”. This bronze reminded me of the feeling that I had as a kid at the Carmel Mission and the Custom House in Monterey. What was accepted as good finish hardware in the US at that time was mass-produced product that had lost the grace of original design and nuanced workmanship. I soon eased out of construction to focus on building a business that would bring exceptional hardware to the marketplace. My model was to assume nothing, learn quickly, and be curious about the whole history of hardware. I discovered the little-known, exquisite period hardware that was being produced in New England and Europe and I felt compelled to give it wider exposure.

Tell me about the Folger + Burt process. How closely do you work with clients? Describe your relationship with the architect and contractor.

We are two integrated entities: consulting and provision. To consult is to collaborate, contribute, and manage the process. Of paramount importance is listening closely to the client’s wishes and fulfilling them. We want to know the full intent of the architect and designer, the needs of the door shop, the security team, and the builder all the way through the project. Our schedules, drawings, and specifications reflect every requirement in detail for the benefit of everybody on the project team all the way through installation. Our job is to meet all expectations.

Who is on your team? What skillsets are required for your niche?

Though most of us grow up turning doorknobs, our world is a hidden one and rarely does anybody have deep experience with hardware. I look first to see if one’s eyes light up by what they see. If so, they likely have a natural interest in our world of material culture. Typically, team members spend a year in Operations being trained by seasoned project managers in the encyclopedia of hardware and our systems. I am the analog guy, with great respect for the deft grasp of digital technology of my younger team members. I still whip out a pencil and scale, but it is a delight for me to watch my team create the digital artwork and schematics we use to illustrate our talking points. I teach them everything I know about construction, architectural concepts, requirements of doors and windows, but most of all, the importance of knowledge, creativity, and an open mind. They also learn to respect the unique character of every project and how important it is to engender effective relationships with all members of a project team. I will ask if they know how the old Italian frescos were made.

The design of your showroom in San Francisco pays homage to the artistry of the pieces you have on display. Describe the vision for the space. Who did you collaborate with on display pieces?

I felt that San Francisco and the Bay Area deserved a quiet, uncrowded gallery of unusual locks and hinges, jewel-like cabinet knobs, the pride of the Bauhaus, and the rich but hidden heritage of America’s finest. I loved how Carlo Scarpa’s exhibits within the Museo Castelvecchio mounted artwork of antiquity as if fresh from artists’ workshops. I wanted to emulate such a place, where everything could be put to the eye and the hand in good light, a meeting place for the careful examination of the objects that we touch and rely on every day. We designed the space and built all our furnishings to surprise visitors with the level of respect we accord to excellent hardware. All was done in service to each client’s search for the right fit-and-feel for their project.

Tell me what it's like to run a small business. What challenges have you faced and what has been rewarding about that?

Small requires Mighty. For us that means resisting the temptation to say “yes” to every request because of the ripple effect it can have on meeting our existing commitments. Also, our world of hardware is quite an eye-opener for most and the complexity of most jobs requires a deep well of shared experience, constant diligence, and adept teamwork. I discovered that maintaining an open forum in the shop encourages learning while eliciting the inner talents of everyone. Problem solving, training in proper assembly practices, careful judgement calls, and the reasoning behind each one of our decisions are all parts of our daily conversation. I urge everyone to strive for 100% accuracy and to “own” each job as if they were going to install everything by themselves on a desert island with one screwdriver.

Which new technologies have influenced your work as of late? How do you think they will change the industry going forward?

Digital technologies have had a tremendous impact on the nature of our work in sand casting, investment casting, and traditional machining. CAD and CNC programming can produce intricate designs that formerly required hand tooled patterns. Investment (lost wax) casting can now be produced without loss of detail using CNC machining. Rapid prototyping is particularly valuable for all production methods when developing new creations for approval. Mass production does not welcome change though most people are interested in options to the status quo. These digital tools are enabling true custom design to be more accessible to those clients.

Our studio deeply values working with purveyors and artisans who are experts in their trade or craft. What is special to you about high-quality, bespoke goods?

I think of bespoke as uncompromised design and execution with a distinct identity. Conventional hardware has its place in the world. Our focus is on meeting the specialized needs and discerning taste of our clients. I’ve had the privilege of working with true artists and extraordinary engineers over the past 25 years, collaborating with them to invent, design, engineer, and fabricate original hardware specific to each job. I believe that the opportunities to produce and deliver bespoke work come to us because we welcome and embrace the process of discovery in design development and of the impeccable craftsmanship required.

Many years ago, an architect asked me to design and fabricate long, dummy strap “hinges” in bronze for the garage door of a Big Island home. I jumped at the challenge, researched Hawaiian canoes and, lo and behold, I was soon in the smithy with a local blacksmith making canoe paddles, again. The doing was its own reward and fortunately the bronze “paddles” were well-received.