Designing with the Carbon Budget: Fog's Edge

In this blog series, we'll deep dive into specific projects, outlining how we're tracking both the predicted operational and embodied carbon emissions as the project progresses, which in turn, will result in more sensitive and resilient designs that emit less carbon.

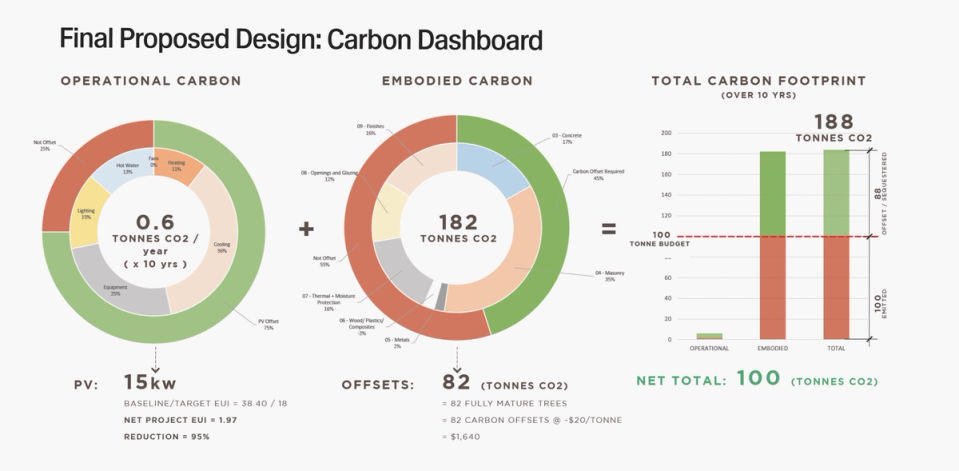

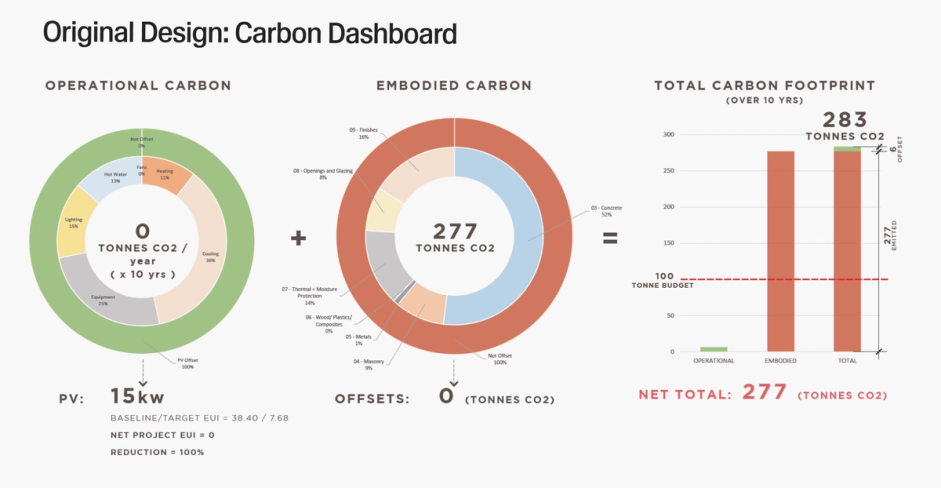

Introduced in 2023, our Carbon Budget takes aim at each project’s operational and embodied carbon, setting an aggressive target of 100 metric-tons (tonnes) per home. Our carbon dashboard measures the projected carbon emissions of each project throughout every design phase via energy modeling and embodied carbon analysis, using this to data to further optimize our designs. Since the launch of this initiative, we’ve implemented the dashboard on 11 projects.

Fog's Edge, a new home with a detached garage/ADU, curves gracefully with the land on a particularly scenic lot in the Santa Lucia Preserve. As one of the first projects we've designed using our carbon budget initiative in earnest, the process presented a steep learning curve to the design team - it was our first time tracking a project's carbon footprint across all phases of design. Soon after kickoff, we introduced the initiative to the clients, and actively integrated a dedicated member of our Sustainability Committee into the project team as a resource - answering questions, offering design suggestions and direction on tools the team could deploy during each phase to continually assess the carbon impact of proposed design solutions. We used Climate Studio for daylighting and energy modeling to measure operational carbon, as well as Tally to track embodied carbon. Below, we'll outline how the Carbon Dashboard influenced the project's predicted operational and embodied carbon emissions and resulted in a design with a significantly reduced carbon footprint when compared to its original design.

Operational Carbon

The project's operational carbon refers to the greenhouse gas emission produced during the day-to-day operation of the building. Our goal is always to have the building functioning at net zero operational carbon. To mitigate operational carbon, we use energy modeling software to perform a thermal + daylighting analysis, and to right size solar panels (PV arrays), reducing future emissions.

Climate Studio (a plugin to our 3D modeling software) tracks the operational carbon associated with the project - there are several different ways in which we use the tool:

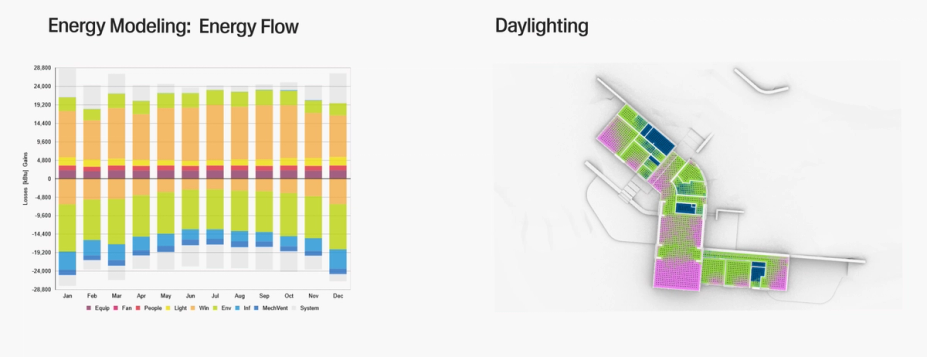

Daylighting studies help assess building orientation, indicate which spaces are underlit or over lit, and show where glazing could be impacting the interior light quality or energy performance of the building.

Energy Modeling: In the past, we've typically relied on mechanical engineers and Title 24 (California's building energy efficiency standards) compliance to understand the required energy loads and PV system sizes. With Climate Studio, we run the energy modeling software internally to determine energy loads and PV system sizes earlier in schematic design, which gives us more accurate electrical load requirements.

One trend we've noticed after running Climate Studio internally is that T-24 energy modeling often indicates a much smaller operational carbon footprint than what is measured in Climate Studio. For Fog's Edge, the net EUI (Energy Use Index) determined by T-24 compliance was measured at -13.78 (much better than net zero), while the more accurate modeling from Climate Studio produced an EUI of 1.97. An EUI of 1.97 is a 95% reduction from the 2003 baseline EUI of 38 set by the 2030 commitment, which currently targets an 80% carbon reduction from the baseline. Therefore, this project is beating the goal by 15%. In 2025 the target will increase to 90% reduction.

Embodied Carbon

A building’s embodied carbon refers to the greenhouse gas emissions associated with the structure's construction - including the extraction, manufacturing, and transportation of the materials used in the project. We used Tally to measure the embodied carbon across multiple phases of the project. Typically, the components associated with larger embodied carbon footprints are concrete (which often counts for up to 50% of the carbon footprint of a home), structural steel, aluminum, and insulation (spray foam insulation is toxic and has an extremely high carbon footprint).

Original Design (277 mT):

In the early stages of schematic design, before our embodied carbon analysis, the project tracked around 277 metric tonnes of embodied carbon emissions. The early embodied carbon analyses identified that the high emissions were a result of a full basement, a baseline 25 - 50% cement replacement in concrete mix, aluminum doors & windows, a steel-heavy structural system used for cantilevers, and the sourcing of foreign stone products.

Final Design (182 mT):

After assessing the largest contributors to the project's embodied carbon footprint, we were able to modify the design to reduce emissions to 182 metric tonnes, which is a significant difference. The most straightforward way to reduce a project's carbon footprint is by cutting down the building’s overall square footage - we worked with the clients to reduce a full basement into a partial basement and modify concrete slabs into wood framed floors. Concrete retaining walls were replaced with reinforced masonry walls, which use low-carbon CMU with a high recycled aggregate content. Almost all structural steel in the project was eliminated and replaced with mass-ply roofs and floors to achieve the cantilever as originally designed. Introducing mass timber, which sequesters carbon, upgrading to wooden doors and windows, and specifying locally sourced stone from within the state as well as a concrete mix that replaced 70% of the Portland cement with slag (a byproduct of steel and iron manufacturing) and low-carbon CMU’s were some of the key levers to drive further reductions.

When combined, these efforts reduced the embodied carbon footprint by 95 metric tonnes (34% reduction from our original design).

Overall Carbon Reduction

Through our use of our carbon accounting and reduction strategies throughout the design process, the team was able to reduce the project's overall carbon footprint by 240 metric tonnes.

Original Design Carbon Footprint (without PV system) measured over a 10-year period: 154mT operational + 277mT embodied = 431mT

Final Proposed Design Carbon Footprint (with full PV system) measured over a 10-year period: 7.7mT operational + 182mT embodied = 189.7mT

We're looking forward to continuing to streamline our processes through a more effective use of analyses software and low-carbon product research and strategies, as well as further engaging clients and consultants on current and future projects to reduce our carbon footprint.